Over the course of the last few years the maximum number of queries I’ve received from my readers has been around the type of wood to be used and the what wood specification one should look for for different interior applications.

While part of the above query is answered in my earlier article on “What Material to use for Woodwork” I guess looking at the number of questions that have come in on the topic there is need for the article to be much more descriptive especially around the type of wood and their specifications. This post will try to do just that, also please read this in conjunction with the earlier post (“What Material to use for Woodwork”)

Note: None of the Images below are my own – these have been downloaded either from Wikipedia or other open sources

1) TYPES OF WOOD FOR COMMON WOODWORK

|

| PLYWOOD |

A] PLYWOOD:

Most people recognize this. These are sheets of wood pasted together. However plywood comes in many specifications based on the chemical treatment of the wood and the glue used to bind the sheets together which determines its type of use – see the specifications section below.

Also – Plywood is available in multiple thickness from 2 mm to 38mm

|

| BLOCK BOARD |

B] BLOCK BOARD:

This is cubical stocks of wood sandwitched between two thin sheets of Ply. As is obvious from its construction block board has higher resistance against warping or bending. It is available in the standard thickness of 16, 19 & 25 mm

Again Blockboard comes in different specifications that determine its use in interior applications…more on that later

|

| MDF |

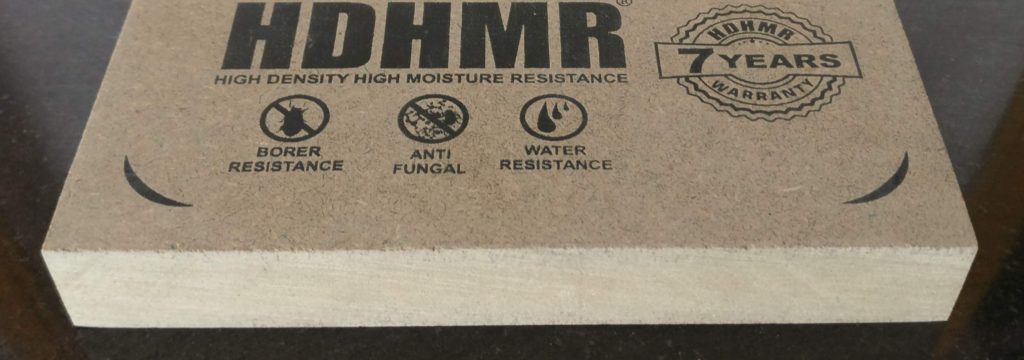

C] MEDIUM DENSITY FIBRE (MDF):

MDF in engineered wood basically made from wood pulp. As is obvious from its construction MDF has low resistance to warping/ bending & moisture. Also nails do not hold well to join MDF sheets together, they need to be either screwed or joined using a minifix (google for it…). Because of this a lot of carpenters are not comfortable working with MDF. The good thing about MDF however is that you get “pre laminated” MDF in different colours, shades & textures and if used intelligently it can help bring down the cost of construction & also enhance the look of woodwork.

D] PARTICLE BOARD:

This is chips of wood glued together and pressed into sheets. Particle board is the cheapest of the above 3 options, it however has least resistance to moisture. Because of its low density & weight Particle board offers good resistance to bending especially in applications requiring long panels (such as a 9 foot high wardrobe doors). Particle board also is available in “pre laminated” form and its correct use can help bring down construction cost.

2) WOOD STANDARDS AND SPECIFICATIONS:

Indian standards are not very well documented and there isn’t much user understandable documentation available. What I have mentioned below is built on current market terminology & the products available in the market for a layman to make sense of the same. The paragraphs below are not meant to stand up to an ISI inspection but should definitely help “YOU” make informed decisions.

A] “Plywood” Standards and Specs:

1. IS 303 Specification: This is the ISI or BIS Specification for Plywood. This is further divided into (1) MR Grade and (2) BWR Grade

- MR Grade: Stands for Moisture Resistance – MR Grade Ply is basically regular plywood. This is also sometimes called Commercial Ply. In laymans terms this can be used everywhere except in the Bathroom & Kitchen.

- BWR Grade Plywood: This is Boiling Water Resistant Plywood. Some companies call it BWP (Boiling Water Proof) Grade however the Bureau of Indian Standards has officially done away with the BWP terminology. In layman’s terms this wood is also mentioned as Marine Ply & is for use in the Kitchen & Bathroom.

Note: Recommendation for Kitchens is therefore “IS303, BWR Grade Plywood” – The shopkeeper in the wood store will have little to fool around if you use the above phrase. Simple isn’t it 🙂

2. IS 710: This is the “Formal” Standard for “Marine Grade” Plywood – used for making boats & ships…hence this is topic for a blog on shipbuilding & not here 🙂

B] Block Board Standards and Specs

The Bureau of Indian Standards has the IS 1659 Standard for Blockboards. Again this is subdivided into MR Grade (Commercial Board) & BWR/ BWP Grade (Boiling Water Proof)

Explanation on where to use blockboard and where to use Ply is on my other post at What Material to use for Woodwork

C] Standards for Particle Board and MDF:

In India Particle board & MDF are at a stage of nascence where they are bought based on the Brand Name rather than on the ISI Standard. Some manufacturers do cite exterior Grade & Interior Grade MDF/ Particle Board, however personally I prefer to go with a good brand and the range of colours offered than the “Grade”.

That does it for now I guess and as always would welcome any Bouquets & Brickbats

Signing off

Nandita

PS: If you have a question to ask then please note: The Q&A/ Comments interface on this blog below is unable to scale to the number of questions that we have been getting. Hence even if you post a question I will be unable to reply to it due to technology limitations. To do away with this issue we have launched the Q&A module on The Studio website.

Hence if you have a question or if you posted a question earlier and did not get a response then please post it again at https://thestudiobangalore.com/questions-and-answers/ so that I am able to see and answer it

Regrads

Nandita

271 thoughts on “Types of Wood & Wood Specifications for Home Interiors”

Thanks a lot for sharing your knowledge. This has surely helped me.

So, what you say is, as long as it is ISI 303 BWR grade plywood we can go ahead with any brand right? I am from Bangalore and I was actually thinking of going with either GreenPly or CenturyPly but the cost would come down if I use Green touch Ply or some other local brand instead. Do you think going with other brands would be fine even for Modular kitchen purpose?

Century & Greenply are definitely better in quality, but if you have a budget constraint its ok to go with any other brand – just ensure that it is ISI Marked 303 BWR Grade

NM

What if I'm using a Veneta Cucine which also uses particle board for their carcass. Is it better to go to a local vendor who uses marine Ply? I'm not to fond of the design and quality from local vendors. Does the life of my kitchen still reduce if I use a veneta kitchen?

Nihad: Life of Marine Ply will always be more than Particle Board. Find someone who can give you a Veneta class designs in Marine Ply.

NM

This post has very good information for us to equip ourselves before meeting the hardware/ply shops which will save us from being taken on a ride !! Thanks a lot nandita for sharing this info.

I am planning to do the interiors for my home and since i like involving myself into this kinda work, i plan to get things done by a carpenter.

While doing my research on materials, i have come across the following points and seek your help to get clarifications:

1. Any ply/Blockboard of IS-710 or 303 is good enough for kitchen, if it comes with ISI marking (hoping its not fake). Any Not so premium but good quality brands that you suggest ? (i saw woodBlock (80/sft), LG (65/sft) Alishan (94/sft))

2. What is your take on Veneer face plywood ? I have seen a 19mm ply & Board which has a smooth american tulip style veneered face on both sides. (this can bring down my cost of laminates on inside & outside, if i opt for transparent paint finish). Cost is 63/sft for MR grade. This can also be painted inside & polished outside (melamine is what i m looking at). Any other budget options like a water based polish with brush application ?

3. For the Modular Kitchen, i have been to a showroom near Pai function hall, south end circle. They have a lot of stuff on display with huge range and the company is ENOX. They say the quality is in the premium levels like hettich and cost is low coz its made in india. Any idea about this brand and its life ? the warranty they provide is lifetime for most of the stuff they sell, hinges, channels, tandem boxes etc

4. If i want my kitchen to stand on steel stands of 3 or 4 inches, to make it easy to clean the floor regularly, how is it to be designed ? Can a regular carpenter working with marine ply take any help from me (internet) and get this done ? I dont think its hard, but i guess i need to tell him clearly on "how-to" and give him materials. So what kind of materials and planning needed ?

I hope my understanding with materials & usage is ok and would seek your help with the above points. I want to do it myself to have my say & knowledge on materials, but at the same time, i dont want to end up in a messed-up wood work. The carpenter is known to me for quite some time and accommodates new suggestions without protest 🙂 !

Once again.. thanks for your blog.. it does inspire people to learn and takes things in control with the interiors at least 😀

Krishna – All your questions are already answered in earlier posts or their Q&A/ Comments. Please refer

http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

and

http://www.homedesignbangalore.com/2010/06/so-what-is-modular-kitchen-and-some

What is not there on the posts above and you have asked is

1. Enox – It is a good brand for Hardware, you may also try EBCO – both these will be marginally cheaper than Hettich but similar in quality.

2. Using Veneer Faced Plywood – This is cheaper but is usually not ISI Marked & not available in regular brands – so a lot depends on pure luck. You will still need to polish this (advisable not to be too innovative here) – hence you may not end up saving much vis-a-vis Laminates

Rgds

NM

Thanks a lot for your immediate response Nandita.

I have decided on not being too innovative and hence dropped the idea of using an unknown plywood variety.. even my carpenter was not sure of the quality of the plywood.

I have read through your archives completely 🙂 and now a lot more informed than before !! Thanks again for the wealth of information. After reading your blog, i went to hettich showroom in Raheja and figured out what you meant with the "Brushes on the sides" for sliding units. I decided to stay away from sliding stuff completely because i felt it needs a little more care than normal hinged variety.

1. Coming to the hinged doors (for wardrobes esp), my carpenter says the good old hinges (conventional stuff) are better and last longer than 0 crank box hinges (from hettich/enox/ebco etc). What are the downsides of using conventional hinges ? I think with these, the aesthetics are most affected, with a beading coming into the picture ? any suggestions here ?

2. For the adhesive, i m planing to use 3M synthetic resin adhesive instead of fevicol SH, bcoz 3M product is water & heat resistant, quick drying and more coverage. Do you have any experience using this adhesive (3m) ?

3. I have also checked out some shops for edge banding, but most of them say its not as durable as the regular solid wood beading. Can you comment on this ?

my apologies if i m getting into too many details, but you seem to be the right one equipped to answer such queries !

Krishna,

1. Choice of the Hinge is dependent on the design of the Wardrobe. Also zero crank hinges are no worse than butt hinges or piano hinges

2. I have not used 3M adhesive hence cannot comment

3. From a durability point of view a wood beading is definitely superior, however from an aesthetic point of view edge banding scores better. Again the choice of beading is dependent on the design

4. Further questions will attract a consulting fee 🙂

NM

Hello Nandita,

Can i use block boards or commercial ply for covering up kitchen loaft.

Yes

Hi Nandita,

are you still available for interior design?

We just bought a rowhouse and its still under construction. I would like to know if I can involve an interior designer early on so no re-work needs to be done.

I am looking mainly for

kitchen

sliding wadrobes as my rooms are a bit smaller. Can you send me more details on ramya dot nitw @ yahoo dot com

Hi Nandita, I stumbled on your great blog and man, I should say I'm relieved. I'm starting to learn the ABCs of interiors.

I have purchased a new home and am about to do the interiors, so there are plenty of confusions. Want to ask you about some of these:

1) On the wardrobes, one carpenter suggests the use of MDF BSL (both sides laminated) plywood and the another one suggests using MDF for the carcass and blockboard for the doors. Which option is better and cost effective (without compromising on quality)?

2) In general is BSL plywood a good option? Can I use it across the interiors – for dressers/ wardrobes/ study tables/ TV cabinets etc.? (I have read your post on what material to use, but still confused.)

3) Should I be rather using HDF everywhere?

4) What option is typically cost effective? (I'm including kitchen in this, as I understand that its 'special'.)

5) I see a lot of wardrobes with a glass/ metallic finish (the doors). What material is being used here? How expensive is this?

(I'm sorry, too many questions, but I'm excited that I got an expert to answer.)

1) MDF/HDF BSL is MDF or HDF and NOT Plywood

2) If you dont want to compromise on quality and doing the woodwork on site with help of a carpenter then for Wardrobes use Block Board & for Kitchen use BWR Ply.

Prescriptive recommendation on what material to use is already available on my other post http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

3) Glass/ Metallic Finish seen in Wardrobe photographs is actually Glass or Metallic Laminate

Rgds

NM

Ideal time to engage a designer is just before start of electrical work. You can reach me at nanditamanwani@gmail.com

Rgds

NM

Hi Nandita,

A very nice and educative blog for the beginners like me. Was eager to ask you that there was something called rubber wood (used to be fancy stuff about 7 yrs ago). Any comment on its quality and utily:price ratio?

Thanx in advance

Arnab

Rubber wood is still very much in vogue and is nowadays available in polished/ stained varieties to give a look of teak/ rosewood etc.

In terms of price it is much cheaper than teak however its application is primarily limited to kitchen/ small sized shutters as large panels of Rubberwood tend to bend unless they are framed

Rgds

NM

Hi Nandita,

Need your advice to know what material and specifications to be used for making a divan bed in master and guest bed rooms?

Appreciate your early response

Arup,

The choice of material for beds or diwans is primarily dependent on the design – you could use anything from Particle Board, MDF, Plywood or Teak

Regards

Nandita

Great, thanks for your answer. In plywood material can you please suggest a MR commercial brand (not Greenply, Century or Greenlam etc)? I have a budget constraint and the divan will have a storage facility.

Thanks again.

Arup

I would not recommend MR grade. Any BWR grade ISI marked plywood around Rs 80 psft should be fine

Rgds

NM

Hi Nandita

Wow ure blog was very informative. I am currently renovating my house and all material used is my responsibility. Just a quick query, for the main door and bedroom door i am using commercial ply, what is the ideal thickness for the same. Also for bathroom door and kitchen cabinets i have decided to use BWR, so what thickness should i settle with??

Thanx

Deanna

A ready made main/ bedroom/ bathroom door will work out cheaper and better in looks.

For both side laminated kitchen doors 16 or 17mm ply should be fine

Rgds

NM

Hi..

i am doing wardrobe with both side veneer, now the problem is total ply thickness is 18-4-4 =26mm. "0" crank hinges is not running more then 19mm.. can you pls guide me plz

You will get special hinges for thick shutters – the regular zero crank hinges will not suffice.

Rgds

NM

Is commercial grade plywood recommended for wall shelves in the kitchen?

Regards,

Nagendra.

Yes for the shelves it should be fine

Rgds

NM

hi Nandita,

Which is best ply for making ward robes and kitchen cabinets.Thanking you

Regards,

Hari

Ideally any brand above Rs 80 per sqft for 19mm ply (BWR 303 grade ISI marked) should be fine

Rgds

NM

Hi Nandita,

Thanks for all the information in your blogs. For Beading my carpenter is giving me both the options of teak wood and PVC. for me PVC looks better. Please let me know the downsides.

Thanks,

Sudheer Muttam

Choice of the beading is dependent on the design and the colours. If you plan to use PVC then ensure that the right gum is used else it sometimes comes off

Rgds

NM

Hi Nandita;

Is it okay to to use MDF for wall unit / TV tables & for small size shutters

Thanks;

Jay

Yes, provided that there is NO possibility of any water seepage into the walls. MDF is not recommended for outside facing and bathroom facing walls.

Also go through http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

Rgds

NM

there would not be any water seepage; but still my carpenter is refusing to do it ; actually i told him to use 18 mm MDF + laminate only for shutters & use 18 mm MR Grade plywood where some strength is required… but anyway Thanks 🙂 for your guidance; I will now sort out this very well 🙂

Jay – just to clarify – MDF "Pre laminated" sheet is OK to use, or on a raw MDF sheet use of duco paint is fine. Sticking laminate to raw MDF onsite should be avoided.

Rgds

NM

HI Nandita,

I need some info on MR grade ply wood . Hardwood or Softwood MR grade ply wood which is better for Ward robes?

Please refer

http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

Rgds

NM

Hi Nandita,

I am using 19 mm green plywood ecotec for my wardrobe.

Is this a good plywood?

Thanks,

Deepak

Any ISI marked IS 303 BWR Grade ply with an MRP (in Bangalore) of Rs 90/- per square foot is fine to use

Rgds

NM

Hi Nandita,

I am thinking of using green fly bwr/bwp grade for my kitchen. But i have checked many shops none of green ply has ISI marked.But it is written that it is bwr/bwp. is it ok ? or it is fake green ply? which brand of plywood is the best?

Best Regards,

Anshuman

Thanks Nandita for giving the picture of wood to use

You're welcome

Rgds

NM

Dear Nandita ,

I have a budget home 3 BR. Will you take up consultancy of Designing space efficient ,cost effective(not cheap), Durable woodwork. Please give a price Idea of your proposal

Hello NM,

We are planning to opt for a POLYMER based material for Kitchen Cabinets at our apartment, considering it is water resistant – Can you please advise if this is a better option.

I have not used Polyer hence cannot comment with conviction

Rgds

NM

Hi Sachin,

You can reach me at nandiamanwani@gmail.com to discuss

Regards

NM

Hello NM,

Can you tell me about the Bison Panel?? Is it good for the Kitchen partition???

Bison Panel is fine for paneling, partitions and small sized (under 4 feet) shutters

Rgds

NM

Thanks for the detailed blogs. After going through I got good knowledge about the materials to be used. My carpenter has given a quote as below:

1.Only MR grade BOARD (meaning Block Board) for Wardrobe carcass as well as doors, with 1mm Laminate on the facing and .7mm white laminate inside.

[He does not want to listen to me when I asked him to make the Carcass using MR grade Plywood for the wardrobe & block board for the doors. He says Board is the best for the Wardrobe carcass.]

2.He will use only "Alpine" brand Plywood & Block boards. Is it good brand quality-wise?

3.He will put only 3 Hinges (Ebco) per door for the 7ft height door.(I found that always they use 4 hinges for such doors). I insist on 4 Hettich hinges per door.

4.Edges of the doors in kitchen n wardrobes will be fixed with teak beading and not rehau edge banding.

Pl. guide me whether to accept it or not.

Sivarajan. V.

If you are using MR grade then any ISI Marked ply/ board in the price range of around Rs 80 – 85 per square foot at current prices in Bangalore is fine.

Number of hinges is determined based on the weight of the door…each hinge type has a specific weight capacity. Ebco hinges are broadly equivalent to Hettich.

Beading/ Edge Banding – really depends on your personal preference

Rgds

NM

Hello Nandita,

Thanks for ur quick & informative reply. My specific question is whether Block board can be used for Bedroom wardrobe Carcass? Is it having longer life and durability than plywood?

Sivarajan.V.

Good quality board will have the same life as Ply

Rgds

NM

Hi Nandita,

Please suggest me which is good from teak wood or corian mdf ( acralyc ) for kitchen shutters.

Also commercial ply of thickness 18 mm is good for kitchen cabinets.

Both Acrylic & Teak are fine…choose based on which finish appeals to your individual taste.

Durability of teak is definitely higher but both should last you longer that you would want to tolerate them in your kitchen.

18mm ply for Kitchen Cabinets is fine

Rgds

NM

Hi Nandita,

Really a nice informative blog for first timers like me. Thanks for that.

I had a question, there is a interior designer who is proposing wipro wood for kitchen and wardrobes. I tried to find out more information on net also I wasnt successful. Wanted to know your view on that please.

Thanks

Haritha

Hi Nandita, pls suggest on what flush door we should use for the bathroom. Can i go for Century ply or local brands. I also liked the teak wood laminates is this ok for bathroom.

Thanks

Anuradha

Very helpful information. Can u pls suggest me which wood either MR/BWR is good for show case work

Have never heard of Wipro plywood :(. You may decide based on the IS specification and the ISI mark

Rgds

NM

MR Grade is fine for the showcase provided the wall does not have likelihood of dampening – such as outside & bathroom facing walls.

Rgds

NM

Flush door is ok for the bathroom only if there is zero likelihood of water splashing on the door. Else its best to use regular wooden doors. You may choose the brand based on the budget.

Teak laminates are fine for the bathroom.

Rgds

NM

Hi Nandita,

This is in regards to your post about Waterproof Marine Ply. Please advise on trustworthy shops to buy from, and apt brand(s) please. Many thanks in advance. Can't thank you enough for this blog and the knowledge it permeates out to the public and information seekers.

Regards,

Rajesh Gawde

I cannot vouch for any particular shop since this is a very unorganized market…designers usually have a direct supply chain from the distributors & long term relationships that helps with genuine supply, that unfortunately does not work out for retail customers.

Rgds

NM

Hi Nandita ,

Wanted to check on few points with you

1. We have planned for a crockery unit with washbasin .Since we don't want to loose out on the looks of crockery unit because of the washbasin ,we have thought of granite base for crockery unit with wash sink and the back wall with stone tiles. Will this work out well . If possible kindly give your suggestion in this case.

2, For the TV unit wall , I have planned for wall paper. What's your opinion on the durability of wall paper .

3. With reg to kitchen baskets , which brand is good . Is there any specific grade of SS which I need to check if am not buying a branded basket.

Regards,

PraveenRaj

Hi Nandita, Really a nice informative blog for first timers like me.

My designer has given a spec for my kitchen, i hv mentioned here:::

P & F the Kitchen Cabinet with Membrane finish shutters & Water Proof Plywood cabinets 18mm thik with 0.8mm white lamination inside the cabinet,. (All factory make) inside cabinate 0.5 mm PVC edge beading and door for 2mm edge beading. (

approved color) (BWP CENTCRY 710)

he has quoted 3lakh. could u suggest me on this. please i m confused, he said he is using hettich baskets, tall unit, floor / wall cabinet and loft.

and a crockery unit.

Being in the same line of work I refrain from commenting on quotes of others as it is not right for me to play judge. Apologies that I am unable to help

Rgds

NM

My personal take is that a washbasin in the dining room is best avoided as it makes the place feel like a washing area – however that is just my personal take & your suggestion of having a Granite counter and stone tiled back-splash should suit fine.

2. The quality of wallpaper available nowadays is pretty good hence feel free to use on the TV panel

3. Any SS 304 grade basket should do – choose based on the brand of the hardware used as part of the basket and the thickness of the wire.

Rgds

NM

Hi Nandita,

I am planning to use block board for the interiors for my flat. I have a few questions that I need to ask you.

1. Would you recommend using BWR grade block board for carcass in kitchen and MR grade block board for wardrobes?

2. What do you think the thickness of laminate should be?

3. Will using block board increase the cost of the interiors?

Regards

Responses in line below

1. Would you recommend using BWR grade block board for carcass in kitchen and MR grade block board for wardrobes? – Yes should be fine – however the block board option is not available for factory made carcass.

2. What do you think the thickness of laminate should be? 0.8 mm on the inside & 1 mm on the outside

3. Will using block board increase the cost of the interiors? yes but by no more than 5%

Rgds

NM

Hi Nandita,

I am planning to get the kitchen cabinets & wardrobes done by a carpenter. He is insisting of using Kitply BWP plywood for kitchen; commercial kitply for wardrobes.

1) How is the quality/durability of Kitply as per your experience? If it is not good, which is better than this?

2) What is the current cost of Kitply in Bangalore? What is the price of its better competitor?

Your advice will help me to decide on this.

Regards,

Sumukh Bharadwaj

Kitply is fine however a lot of fakes also sell under the brand, hence you should ideally buy from a trusted source.

For prices please check with the local woodstore. Decent quality BWR Ply will typically start at an MRP around Rs 80 – 100 psft

Rgds

NM

Hi Nandita,

I have a similar question here. I have recently purchased a house where an initial level of woodwork has been completed, including the kitchen carcass. The kitchen carcass has been built with BWP grade board (presumably blockboard) of Commander brand (Ajay plywood industries).

I do see that you have recommended BWR grade plywood for modular kitchens. Do you think that the material used is good enough for the kitchen or should I have it removed and start from scratch with BWR grade plywood. It may be a costly affair to replace it but if it is highly recommended, I will go for it.

Waiting for an early reply.

Best regards

Anuj Mathur

HI Nandita,

Thanks for sharing the details on wood work.

Ysterday we met a carpenter for kitchen work to our new house which is in construction stage.

He suggester Ploymer coated wood and he get the doors in polymer coated done from a factory in Pune and its xpensive.

Where as anoter carpenter said PU coated century plywood he would use. What is the difference b/w PU coated and Polymer coated, r they both same?

Which one would b gud to use as we have made up mind from 1.5K to 2K per sft for kitchen.

What is the rate now in Bangalore for these per sft?

Thanks in advance, waiting for your answers.

Regards,

Vandana

PU = PolyUrethane. In the field PU, Polymer, Acrylic, Hi Gloss, Duco, UV Coated etc. are sometimes used to mean the same thing. There are minor differences in each but the finish (hi gloss) is broadly the same.

All of the above need hi maintenance as over time they tend to develop scratches due to the glossy surface.

Different vendors have a different quality of the finish…ideally you should decide based on the finish.

Rgds

NM

BWP (Marine Grade) is rather better than BWR – hence you should be good to go on top of what you already have

Rgds

NM

Hi Nandita,

Thanks for a really quick response..But the fact is that the existing carcass is made up of board rather than ply. Does that make a difference.

Regards, Anuj

BWP Board is good enough

Rgds

NM

Hi Nandita,

Currently I am planning to start my house interiors. It will be great help if you can answer my queries.

1. I am planning to buy MWP brand Platinum IS:303 MR grade ply with Gurjan wood for wardrobe. MWP Platinum IS:710 MR ply with Gurjan wood for Kitchen. Is this fine?

2. What should be the ideal thickness of sliding door. My carpenter suggesting for 32mm. Since it will be heavy, some suggested me to use 19mm board with 6/9mm frame/beeding. Will this be fine?

3. I am planning to use 90% of hardware from Ebco. How is this brand compare to Hettich or Haffele/Blum?

Regards,

Sunil

Responses in line below

1. What you have mentioned is broadly Commercial ply for Wardrobes and Marine Ply for the Kitchen. If the ply is ISI marked then the selection is fine.

2. A frame construction for sliding doors is better as it reduces the weight and also ensures that the doors dont bend

3. Ebco nowadays is nearly as good as Hettich/ Blum

Rgds

NM

Hi, Nandita

I am planning to interior my flat.. Carpenter suggest to use Alpine plywood dor whole woodwork.is it good quality plywood ? if no please suggest good quality plywood other than century, green, kit. Thank you

Any ISI marked BWR Grade plywood in the price range of above Rs 85 psft should be fine

Rgds

NM

Hi Nandita,

Thank you so much for your valuable information. I have to go for interior to new flat. I am in dialoma whether to go with veneer or Lamination for wardrobas and TV unit. Please advice which one is good and what is the difference on cost wise also.

The choice between Veneer & Laminate depends on your taste. If you choose laminates you will need to look into how you will treat/ hide the edges, while if you choose veener you will need a good polisher else the look will not be up to the mark. Finished Veener in general (with polish) will work out to be much more expensive compared to laminate.

Rgds

NM

Hi Nandita,

We bought a 3BHK and we are using MDF (Nuwud) for our kitchen and wardrobes (18mm thickness). And our carpenter is suggesting Ducopaint for Kitchen cabinets. We are looking for High Gloss..is it advisible to use Acrylic Sheets for Kitchen cabinets and are they durable? And also what would be the Cost of the acrylic sheets or Membranes? What would you suggest?

Hi Nandita,

My contractor is giving plywood choice AK and Apline. He says going for Greenply or Century will add 50,000 for my already stretched budget.

Is it really worth going for the best? what are other option i have in plywood.

Should i go for best quality ISO:710 in lesser known brands?

MDF is not recommended for Kitchen Cabinets, nor is duco paint as it develops scratches over time.

Acrylic sheets & membrane cannot be applied on site – you will need to buy ready made shutters

Please go through the blog post below and the comments under the same – it will provide additional clarity

http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

Rgds

NM

Any ISI Marked BWR IS 303 or IS 710 Grade should be good enough

Rgds

NM

Hi Nandita,

I would like to thank you for your timely replies on everybody's question.

Well, after reading your article, we decided to go for BWR IS303 Marine ply for Kitchen cabinets under the granite platform. And HDF/MDF for others like storage are above hob where only dry containers are kept. An interior designer says they can provide aluminium Carcass (Looked like powder coated) which is completely water resistant. Is it ok if we go for HDF doors with Aluminium carcass. Kindly advice

Interestingly I was asked the same question on another post on this blog – the response is below

"From a durability perspective Aluminium is fine. Personally I do not like the feel of metallic cabinets as it makes the place feel like a railway compartment"

Rgds

NM

how to make difference between MR grade and BWR grade?

every shopkeeper is saying their ply is good and others are bad, even they can print what we want on plywood as per required on low grade material.

How to avoid such fraud to get valued material to the money what we spent?

Hi Nandita,

This is one of the fantastic piece of blog I have ever seen.

I m building a new kitchen and one of the quotation I received says using a 16mm BWP ply for kitchen with hi-gloss laminate sheets.

Is 16mm fine and is high-gloss laminate a suitable material ?

Hi nandita, we are trying to have a high glossy glass and mirror finish combination along with lacquered glass somewhere for the wardrobe , just the kind we see in abroad or if u have seen in Nolte. Can u please let us know where we can find such material . Are these acrylic glass panel? What's the price here?

These are acrylic panels, you can get a similar finish with Hi Gloss Laminates. Both Acrylic & Hi Gloss Laminate options will be available with any good Modular Kitchen vendor

Rgds

NM

16 MM with 1+1 mm laminate on both sides is fine to use. Hi Gloss laminate is fine however it will develop slight scratches over a period of time.

Rgds

NM

The way I see it – you have 3 options

1. Go with the big brands – Century or Greenply

2. Go with a reputed designer – he/ she will have his own procurement chain to ensure quality

3. Get a trustworthy carpenter on your side – carpenters can tell based on the the effort it takes when cutting through the ply and the general weight of the ply.

Rgds

NM

Hi Nandita,

I have wardrobe done using plywood around 7 years back. Of late it has termites and lot of powder materials fallen on my the floor. What is the remedy? Kindly advice.

Check with Pest Control vendors on the extent of damage and whether the infestation can be controlled at the current stage. If the damage is profuse or not controllable then the only option will be to replace

Rgds

NM

Hi Nandita,

I'm from Pune and planning to buy a readymade wardrobe customized as per my requirement. Size 6 feet wide and 6.5 feet height. It will be in 3 separate units ( middle being a dresser with a mirror on the door). What material should I opt for – plywood with sunmica or MDF?

I'm told that plywood bends over time and the doors don't close properly. Also plywood attracts termites, whereas MDF does not bend and is termite proof.

Also the MDF boards (pre-laminated) come in very limited colour/ designs compared to sunmica. I'm really confused.

Please advise as to which material is a better option with regards to durability and look.

Thanks

Please go through http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

Rgds

NM

Hello Nandita,

I am planning to do interiors for my house.

I came across your article and i feel you are doing a great job in helping people who are new to house making.

I am planning to do my kitchen with marine ply (303 grade as you suggested), no compromise there. But for wardrobes (approx 7ft.) and lofts, we were asked to go with pre-laminated particle wood boards(bhutan boards). It was told that durability wise, they are same as MDF and are cheaper as MDF needs extra work of lamination. Another advise was given that we should go with compressed wood(something like CCF) as that is ISO certified.

Could you please explain these three materials and advise which one is recommended for wardrobes.

your help is highly commendable.

303 Grade comes as both BWR (boiling water proof) and MR (Moisture Resistant). For the Kitchen make sure that it is 303 – BWR Grade.

Pre-laminated MDF sheets are very much available hence the explanation does not make sense. MDF as a material itself is more expensive in general. My recommendation would be to use particle board only if you have a severe budget constraint

Rgds

NM

Thank you Nandita this article is very useful for first timers like me .As you say do it right the first time ,I might be able to do it with your help.

Hi Nandita,

I really appreciate the effort you put in through the blog to pass on the best information regarding the interiors.

We bought a new flat in Bangalore and planning for the interiors. I am really confused. From ur blog i understood BWR MR 303 is the best for kitchen. The IS 710 is for boats n ships. But when asked the interior designer told he will be using IS 710 marine ply for kitchen and MR 303 grade ply for other rooms and block board for sliding wardrobes.

Is it that the IS 710 he said only for the sake of saying and he intended to have MR 303 BWR grade?

And in modular (factory made) how to make sure that the material used by them is the one agreed upon. They only fix everything at the site.

Can u please tell is their a way out to check that and is IS 710 ply for kitchen is possible or not?

Hoping to get a reply soon.

regards

Bency

IS 710 is fine to use for the Kitchen. Nowadays it costs nearly the same as BWR Grade. Note that MR Grade is regular commercial ply/ board (and different from BWR Grade) – however MR grade is ok to use for wardrobes.

You will not know what material has gone in, whatever you do – you will just have to trust your designer 🙁

Rgds

NM

Hi Nandita,

Its really a big thing that in today's busy life you actually spare the precious time and effort to answer each and every query. Hat's off to you. You are making so many people breathe easy and sleep well 🙂

I am so glad I found you at the right moment !

We have hired a contractor for our house construction in Bangalore. The first floor is coming up now. For the doors he is saying that he will buy wood from outside, get it constructed and then install at the site. MY worry is how will I know what ultimately went inside? From your earlier posts I understand that readymade doors are a good option. Please recommend a good place to buy ready-made doors for main doors and bedrooms. Really appreciate your help,

Regards,

Ishit

Dear Nandita,

Some one brought a plywood named 'Jevel ( may be Jewel)'. It has a ISI mark and they say it is of good quality for Furnishing the ward robes, kitchen etc. Others suggest to go only for green ply, AK or Austin. What is your suggestion about the quality of the Jevel Ply. I had to take a decision on the ply to be used for my home. I will be grateful if you can compare and give your opinion on this ply

regards

Rama

There are too many brands in the market and its impossible to know the quality of each brand. In general if you plan to use BWR ply then any brand that is ISI marked BWR 303 Grade in the range of Rs 100 psft or above in Bangalore should be ok. For MR grade the price will be Rs 75 psft or above

Rgds

NM

Thanks,

Google for "Flush Doors in Bangalore" and you will find a number of door manufacturers selling their wares.

Since you will have a fair volume you may also visit any of the Interior exhibitions that take place regularly – most manufacturers exhibit their products there

Rgds

NM

Hi Nandita,

I have bought a new house and starting my interior work. My interior designer has suggested me BWR/Billion Wood board and ply and in mica Sonair/Archid. Are they good in quality and in modular kitchen in channel she is suggesting mix of hittech and ozone so please suggest is it good to go

Yes, the choice of material is fine.

Regards

NM

Thanks Nandita for your prompt reply can this material be used for wardrobes and kids bed and study table as well.

Yes

Hi.. I have started my flat woordwork.. I have following questions

1. My carpenter suggest for 25 ply sheets of size 8*4 and 8 sheets of 6mm ply

How many sheets of 0.8 mm inside laminates are required?

2. Are Silicon company laminates are good enough?

3. Which company is preferred for handles and other hardware materials?

Thanks in advance

–Rahul

The amount of material required is best suggested by your carpenter as it is dependent on your needs and the design

Silicon brand laminates are good for Inside Lamination (whites)

For hardware its best to go with either Ebco or Hettich. Handles is more or less an unorganized market hence you may choose the one that you like.

Rgds

NM

Hi, I am seeing lot of good suggestions given by you. I am also planning to do interior now, I am planning to use Ply everywhere with acrylic finish on same. Is it a good proposition and costwise is it cheaper or a bit expensive. Please suggest

Dear Nanita,

I have been reading your blog posts for the last few days and have gone through most.

I would like to know

1. if Trojan ply BWP and BWR grade are good for kitchen and wardrobe respectively?

2. Is 16 mm BWP and BWR ply with 0.8 mm and 1 mm laminate good enough for kitchen and wardrobe respectively? Or is it better to go for 19 mm + 0.7/0.8mm + 1 mm laminate?

Ours is an upcoming flat in coastal city of Mangalore.

Looking forward to your reply.

Thanks and regards,

AJ

I have not used Trojan Ply hence cannot comment, however any ISI marked ply in above Rs 90 psft (for 19mm) should be fine.

Factory made/ modular stuff will be in 16mm ply. If you are getting it made by a Carpenter then you may use 19mm.

Also in Mangalore weather the suggestion will be to use Waterproof Ply/ Board and avoid MR Grade/ Commercial Ply/ Board

Rgds

NM

I have not come across Ply with Acrylic. Most Acrylic panels available in Bangalore are on MDF. Suggest you check out some local vendors and the options available for the relative costs

Rgds

NM

Hi nandita..I wish to get a wardrobe done in my house in pune..material considered is IS303 MR grade ply with isi mark. Is it ok or shud consider ply? Also plz suggest what shud b d size of laminates? Thanks already and appreciate your help

Smita

Material is fine. If you have a carpenter building on site then you may want to consider making the shutters in Block Board. For laminates you may go with 0.8 mm on the inside and 1 mm on the outside

Rgds

NM

Nandita: Your article are excellent. I am planning a Kitchen with Godrej Interio in Chennai for my apartment. They use 18 mm Marine Ply with Merino Laminates for shutters and sheet for carcass/box. Is this Marine ply BWR 303? Are the Merino Laminates good? Is Steel a good carcass material in general and for Chennai. Mine is a semi modular as the granite is already fixed. How do you rate Godrej kitchens in general and their longetivity? Would help to hear your thoughts although I have seen bits and parcels of my questions answered by you.

When manufacturers mention Marine ply it means either BWR Ply of IS 710 Grade ply – both are fine to use for Kitchen applications.

Merino laminates are fine.

I personally do not like the feel of steel – reminds me of a railway compartment. However if you are fine with that and the designs being offered then you may go ahead as there is no issue with the quality of their material as such.

Rgds

NM

I am planning for the interior work for my new flat. In the loft (with&without bottom support / cement slab) and kitchn top units, vendor says that he will be using BWR ply with rear side thickness of 6mm and all other sides with 18mm. Please clarify.

1. Whether it will be mechanically strong to hold the weight of carcass and the contents inside box, when rear ply thickness is only 6mm against other sides and shutter of 18mm BWR ply ?

2. He propose BWP grade plywood for bottom unit in kitchen. Top unit is of BWR grade ? Whether this is good to go or I should insist for BWP in the top unit too in kitchen alone ?

3. What is typical cost for BWR (IS303) and BWP(IS710) type plywood ?

Hi nandita,

Very useful and informative blog. Need some help..have a kitchen approximately 120 sq.ft of woodwork in heat pressed acrylic drawer/ door fronts made about 4 years ago. It was all white almost snow white..but unfortunately has turned yellow over years.don't know why..want to replace them to fresh white. What would be a cost effective and long lasting way? Duco paint over the current fronts or replacing all fronts with marine ply and fresh white Hi gloss laminate. As per Carpenter current fronts will not take laminate since they are super smooth. Laminate cost with ply going somewhere close to 70,000. Can you suggest cost effective and long has option? Appreciate all your inputs.Thanks in advance.

Paint on top of Acrylic won't work. I suggest you replace the shutters with factory made UV coated MDF shutters – these are available with most modular vendors.

Rgds

NM

Back panels are usually 6 mm. The box will be able to take the weight.

While I prefer to use a single material (BWR/ BWP) for the entire Kitchen since there is not much cost difference, it is ok to go with what your designer is suggesting

Both BWR/ BWP (ISI Marked) will cost between 90 – 120 per square feet.

Rgds

NM

Hello Nandita,

Excellent post specially for modular kitchen. I want to know that even I can ask for Warterproof Marine Ply (Technically called BWR 303 Grade Ply….ISI Marked preferred to the merchant but how I can recognize it that this is original not duplicate. Since I don't have any idea about the originality of material. Please reply.

There is no way you can tell on the face of it. On cutting if you find hollow spaces in the cross section would mean that the ply is not standard quality. Also in fakes the cut cross section will have a lighter colour than the original edge. But frankly even the experts sometimes get taken for a ride – hence to avoid issues it is best to buy from a known source

Regards

NM

Hi Nandita,

I am undergoing woodwork for kitchen and wardrobes.

using these materials

Kitchen: 12mm MR Plywood backside , 19mm BWR plywood partition walls, 19mm BWR Block board for shutters

Bedroom: 6mm MR plywood backside , 19mm MR plywood partition walls, 18mm Block board for shutters.

Queries:

1) is it ok to put 12mm MR Plywood for kitchen backside?

2) is it ok to put 19mm MR PLYWOOD for partition columns in bedroom wardrobes, my carpenter is insisting to put PINE WOOD blockboard !

3) Is it necessary to do beading for all the shutters made up of BLOCK BOARD? my carpenter is saying only the laminate would be sufficient, but i insisted to put beading, since there will be some gaps in the block board when cut !!

4) Using HARDWOOD composed , Plywood/Block board better then PINEWOOD composed Plywood/Block board?

Read through all your comments, i am using ISI 303, 1679(Something to BB BWR), All materials in HARDWOOD, quite heavy to lift. when these ply/BB are cut, i can see some gaps like some layer is missing for 3-4 cms , things like this.. Can i expect 0 mm gaps in higher brands like century, kitply?

Your thoughts will be really appreciated.

Hi Nandita,

what will be right thickness of plywood to be used in modular kitchen. Please reply.

Hello Nandita,

Is it good to go for Nova sheets (pre-laminated on bothsides) for interior work instead of using Plywood.

Thanks,

PK

hi nandita,

great information .i need to know whether postform banding is preferable or edgebanding

Its one's personal choice. I personally prefer Edge banding as it gives a clean and defined edge/ look.

Rgds

NM

I have not used NOVA sheets hence cannot comment. What you do need to check is what is INSIDE the laminate – is it MDF/ Particle Board or Ply. The advantages/ disadvantages of each are available on this blog.

Rgds

NM

It should be 16 mm ply with 1+1mm laminate on both sides

Rgds

NM

Responses in line below

1) is it ok to put 12mm MR Plywood for kitchen backside?

NM: Yes

2) is it ok to put 19mm MR PLYWOOD for partition columns in bedroom wardrobes, my carpenter is insisting to put PINE WOOD blockboard !

NM: I would not recommend using Pine Wood. Use the same standard hardwood across

3) Is it necessary to do beading for all the shutters made up of BLOCK BOARD? my carpenter is saying only the laminate would be sufficient, but i insisted to put beading, since there will be some gaps in the block board when cut !!

NM: Yes, beading is necessary, Laminate on 19mm edges sometimes chips off

4) Using HARDWOOD composed , Plywood/Block board better then PINEWOOD composed Plywood/Block board?

NM: I would recommend using regular Ply or Block Board

Gaps will always be there in block board but not 3-4 cms. Good quality material may have gaps of upto half a cm

Hi Nandita,

What should be the thickness(16 mm or 18 mm) of the plywood for 7*9 sliding wardrobe.

Is it fine to use 1mm laminate inside and outside.

Hello Nandita,

For kitchen, what options are available for scratch proof shutters? Acrylic vs Hi gloss finish. Any other alternatives for scratch proof laminates?

Thanks a lot

hi Nandita,

i have used sliding veneer doors after one month it slightly get bend how to avoid bend in the polished doors pls suggest me

also let me what would be best option for sliding doors ?

rdgs,

vanitha rajkumar

Hi Nandita,

Thanks for sharing the information. I've read your previous comments & post reg use of gurjan wood, still wanted to know if non ISI Gurjan wood is fine ? as they say its imported and hence dont have ISI mark. The other choice then is 710, in which brands have ISI mark. Pls advice. Thanks.

With 1mm laminate on both sides it will be best to use 16mm block board for the sliding shutters. If you are not able to get block board then Ply is fine. Block board is preferred as it has better warp resistance.

Rgds

NM

Acrylic and Hi Gloss is the same finish. The best scratch resistance is offered by Hi Gloss MR TUFF laminates or Hi Gloss UV Coated surfaces.

Rgds

NM

You can get a shutter stiffner and install it along the back of the shutter. It is available from Hettich, Ebco and Hafele.

Sliding doors should be in an aluminium frame or in Block Board with full length metal handles to help avoid warping.

Regards

NM

I will recommend using one with an ISI mark, that said the mark just reduces the probability of getting bad wood as there are a number of products available in the market with fake stamps/ brands. There are hundreds of brands that have ISI marked products.

Rgds

NM

Hi Nandita,

I am planning for my home interior & I do not have any idea what wood to choose. So need your advise & help for choosing wood for below.

– Modern Kitchen

– Wardrobe

– TV Unit

Hi Nandita,

Which is better option from durability point of view:

Factory pressing of laminate and edge-banding vs manual sticking of laminate and applying teak beading

I heard from my friend that manual laminate sticking would result in peeling off after few years . Is this true ?

Pls help in getting information on this.

thanks a lot

Prasad

Please refer http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

Regards

NM

If you have a very good carpenter then either are fine. Note that you will need to polish the teak beading, this is not required for edge banding. You hence need an additional polisher if you go for teak beading.

If done properly then manual laminate on ply will last as long as factory pressed – there are horror stories with factory pressing as well hence who is doing the job is what really matters.

Rgds

NM

HI Nandita,

I have given work to a carpenter to which I had recommended to use 19 mm BWR plywood. He has followed the same but in some places he has used 6mm plywood on back side of the ward robe. I am not sure if this is fine or not ?

for the doors of the ward robe he has used block board (MR) saying BWR block board is never manufactured.

Please let me know if this is right

6mm for the back panel is fine.

BWR Grade Block Board is definitely available. For a Wardrobe even MR grade is fine hence you necessarily don't need to redo it.

Rgds

NM

Hi Nandita,

If you are aware, can you please point me to plywood wholesale dealers?

I want to buy around 160 pieces of plywood.

Hi Nandita,

I am starting the research for doing interiors in my new apartments and wanted your help on the following queries –

One interior guy has told that he will be using Alpine ply. If it is MDF he suggested Green. Do you know if that is a good brand ?

For the kitchen bottom he will be using BWP Marine ply IS 710 grade. Is that better or cheaper compared to ISI 303 that you recommended ?

For the baskets he recommends a company called In and Out. Would like to know what you think about it.

thanks,

arun

Actually it may make sense to try some of the new online vendors such as msupply.com. Even their own vedors are listed on their sites and you can contact them directly.

Rgds

NM

I have not used Alpine hence cannot comment. Green MDF is fine, you may also check Action TESA & ASIS

710 grade is better than 303 grade

There are many brands for baskets hence its best to just insist on SS 304 grade steel

Rgds

NM

Hi Nandita, can u please suggest me whether we can use PVC for wardrobes (only inside shelves) and also in modular kitchen shelves with wooden shutters, as is suggested by my Interior Designer. Is PVC costlier than wood?

PVC shelves in 16mm or above are fine as thinner ones may buckle. These will work out costlier than regular wood and their colour may not match with the inside of the wardrobe or the drawers (In Laminate on Ply) – hence I am not sure why one would use. If there is a logical reason for which this is being suggested then please do send in the feedback as I may also learn something new

Rgds

NM

Thanks Nandita for your prompt reply.

My designer has suggested PVC for protection against moisture as well as termites. We understand there wl b difference in colour, however, we intend to use PVC only for the frame and shelves with wooden doors.

As for the kitchen, our Designer has suggested PVC in case there is water retention on the counter edges as PVC is waterproof as well as more durable.

Do let me know if these reasons sounds convincing as I am yet to say 'Yes' for this option.

Rooma Biswas

Hi Nandita.. green ply gold is good for kitchen base??

PVC is not a proven material for cabinets. This may sound old fashioned but I will suggest sticking to regular plywood.

Rgds

NM

Yes

Rgds

NM

Hi Nandita, the way you are giving the advises to the people is amazing.here i have one doubt about it,is rolex gold ply wood is good?how much it cost would be?bwr grade for the kitchen and commercial ply wood for wardrobes. Could u pls suggest us with thickness of mm and chooing of laminated sheets which one is good.we r eagerly waiting for ur reply .thank you

Hello Nandita …

May i ask some doubts…

1. which type of material shall use for making modular kitchen of my house to get long durability with good looking ? pls sujjest 2 brand….

2. Our contractor has recommended an idea, which is all kitchen wardrobes can be make with feroslab cement, and it's face work can be make with good looking material like plywood,mdf or aluminium…

will this idea provide long durability for the fixing of hinges and good looking from outside view ?

if this will be enough to proceed, what material shall use for the facework with the feroslab….?

My interior guy asked me to use kitply royale bwp for kitchen and commercial for wardrobes. how good this is compared to kitply gold? is it ok to go for it?

aniket

Hi Nandita,

I am looking for recommended thickness of ply to use for interiors of new house.

Could you please suggest the recommended thickness for

1.kitchen drawers, shutters and lofts

2.wardrobes(bigger sizes 9*6)

3.beds(king size)

4.study units

Thanks in advance,

Sameer

All your answers are available at http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

please also go through all the comments under the post above ant this one

Rgds

NM

For choosing the right material to use please refer http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

FOr the wardrobes I will recommend using regular plywood or in case of a budget constraint use MDF

Rgds

NM

Either is fine. Kitply has a lot of duplicates available in the market hence you just need to be careful that the product is not fake

Rgds

NM

For Kitchens, study units & Wardrobes, assuming you have laminate/ veneer on top, anything between 16 – 19 mm is fine – try and contain the finished thickness under 21 mm.

Bed should be in 19mm ply/ board.

Rgds

NM

Hi Nandita,

Builder gave us wardrobes as well made with granite slabs, I want to put doors now.

1st Wardrob has 6.5 feet width 8 feet height middle divided with bricks. Can we get pre-laminated doors for these? If so which brand you suggest?, trying to see for less work of carpenter.

Hi Nandita,

I want to put doors to wardrobes and lofts, Suggest me what brand wood i need to purchase.

1. first wardrobe has dimention like 6.5feet width and 8 feet height. In middle we have brick wall of 5 inch. I want to put 4 doors each.as i dont have much space available for big doors. Whether we can get any pre laminated/ready made doors each like 1 feet small doors along with frame?

2. 2nd wardrobe has total 6 feet width having 8 feet height. but there is no partision with bricks. here also I want to put 4 doors.For this blocked board is best or here also we can get ready made doors along with frame?

2. On top of these 2 wardrobes we have loft as well, its 3 feet height.

Please Suggest me a brand which is good interms of readymade doors/or which ply wood i need to go with brand name.

Hi Nanditha,

Amazing site. I have just one question. Some suggest 19 mm ply and some are okay with 16 mm ply for kitchen cabinet. With the latter be able to hold the weight of the granite counter top? Is it necessary to insist on 19mm ply?

What is the recommended plywood thickness for kitchen, loft and wardrobe.

Hi Nandita, Thanks for your Information. It is very useful to get an idea about wood work.

As per your information, I would like to go with Century Ply (water proof) for kitchen area.

For other area, I will go with Commercial Ply.

1.Can you pls suggest, which brand commercial ply woods are good?

2. Is there any adv/disadvantage is there, when compare post forming with Edge binding?

3. If I go with postforming, which brand lamination sheet is good (cost effective as well quality)?

Dear Nandit,

How to ensure duplicate of Kitply plywood

Pre laminated doors are available for your needs. Please check with your nearest modular furniture vendor

Regards

NM

It will be difficult to make out. Usually duplicates would weigh less than the original. In addition a cut section in a duplicate will show hollow spaces and gaps.

Rgds

NM

Any ISI marked Commercial Ply in a price range of Rs 70 – 75 psft should be fine

Both Post Forming and Edge Banding have their relative advantages & disadvantages – there is nothing that can rate one over the other

For laminates please stick to regular brands such as Merino, Century or Greenlam

Rgds

NM

If you are laminating both sides then anything from 16 mm to 19mm should be fine

Rgds

NM

16 mm with both side laminate should suit fine

Rgds

NM

You can get customized doors in prelaminated MDF from your local modular kitchen vendor. Suggested brandsfor Prelam MDF are ASUS & Action Tesa

Rgds

NM

Hi NM,

Thanks a lot for the useful information.

What is your opinion on using Pine B/B or Euro B/B for kitchen Loft and wardrobes. I am planning to go for sliding doors in atleast 2 of the 3 bedrooms

Pine not recommended. Euro Hardwood (ISI Marked) is fine

Rgds

NM

Hi Nandita,

Thx for great informative blog. I had few queries on the material choice for kitchen shutters –

1. Between acrylic and laminate ( matt or glossy) for kitchen plywood shutters which one is better in terms of durability, maintenance and cleanliness and why? How is the acrylic finish prepared. Is it acrylic sheets. What does acrylic sheets contain in terms of material composition? We are not keen on membrane mdf.

2. For wardrobes and other woodwork which is the best finish – matt or glossy?

3. Among granite or quartz which is more durable and long lasting less maintenance material. Already read your blog.

Hi Nandita,

your blog is really an eye opener for the novice.kudos 4 the great job.. pls let us know your opinion about " multi wood" ( u pvc resin) which is widely used for kitchen cabinets nowadays esp in Kerala and finished with duco paint. Pls enlighten us including durability, hinge stability, the finish , and multi wood vs is 303 bwp Thank you.

hi Nandita

Ur blog is really informative. Thanx for all the information. I am planning for doing the 2bhk interior in Pune and my designer insists on 303 MR grade as a whole and also in the kitchen above cabinets and bathroom as she says BWR is not necessary in the above cabinets.

1.And for the wardrobes she is giving us 9 mm thickness of ply at the back ( which I suggested 12mm) and 18 mm at side and 25 for slides. Will this be ok?

2. Can u plz even let us know what is the best thickness for the laminates we use on the outer side and also the inner. Will 3 mm be fine or 4mm on the outer and 1 mm in the inner for a good finish.

3. Do sliding door wardrobes cause problem later. Which pull out or sliding doors u recommend and if sliding door wardrobe what care do we have to take while making and later on in use.

Thanks a lot waiting and for ur answer

Sayed

Your questions are already answered in the comments above, please take time to go through. Please also go through the following posts and the comments underneath each

http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

http://www.homedesignbangalore.com/2010/06/so-what-is-modular-kitchen-and-some

http://www.homedesignbangalore.com/2012/05/what-material-to-use-for-kitchen-slab

Rgds

NM

I did explore multiwood some time back but was not convinced of it's long term durability and decided to stick with ply. I however cannot claim to know for sure how the multiwood will pan out in the long run

Rgds

NM

hi Nandita…

I am in blore, started my wood work through a carpenter

The carpenter has got BWR century ply and MR board yesterday….but the ply is wet on 2 borders….

Should he use it? I am telling him to cut the wet portion off and not use it….but he says this ply has lifetime guarantee and nothing will happen..!!

if the wood is not swollen due to the water then it is fine to use after it dries out

Rgds

NM

Hi Nandita,Your blog is really very informative for newcomers.I want to make bed and study table with solid wood frame.Plz let me know which solid wood is good for bed n study table frame.Thanks

The frame should be in teak wood, however there are different variety's of teak available in the market and you may choose based on your budget.

For the Study table one does not necessarily need a frame and you can build nearly any design without a frame…and save some money

Rgds

NM

Hi mam, based on your recommendation I have choosed following things for my new apartment.

1. IS303 BWR grade plywood either century or greenply for kitchen

2. IS303 MR grade for other wardrobe and doors.

Now my question is on the thickness of the plywood and laminate to be used for kitchen, wardrobe and pooja door. How much thickness plywood to be used for Sliding wardrobe especially.

Thanks

In case you are laminating both sides or planning veneer on one side and laminate then 16mm ply (with a net thickness of 19/20mm with the laminates/ veeneer and the adhesive in between) is enough. For the sliding wardrobe it is recommended to use blockboard of 19mm in case you are not using aluminium frames.

Rgds

NM

Hi Nandita,

I am starting my interiors tomorrow. I had a query regarding the thickness of the ply to be used in different parts of the wardrobe.

1. My carpenter is giving a 6mm ply with laminate on inside for the backside. Is this fine?

2. What would be the recommended thickness for the shutters of the wardrobe? My carpenter is suggesting 12 mm ply.

3. For a 7 feet sliding wardrobe, is 19mm board with laminate enough?

4. What is the recommended thickness of the ply to be used for the shelves?

Thanks.

Hi Nandita,

I am planning for my flat wood work. My Carpenter suggesting for Gurjan ISI 710 19mm ( BWP Grade ISI 710 ). Is it worth of opting this brand. I did not find in Google of this brand at all. Does it known brand or not

I am planning to get the interiors started this week.

I had a couple of questions on the materials.

1. Green Echo Tech and Green Gold – are these fine for the wardrobes and kitchen respectively, or there is a scope of changing and reducing the price?

2. Planning complete soft close for kitchen. Heard Ebco soft close is better than hettich. Is this correct?

3. Also tandem boxes between ebco and hettich, which is better?

4. Other channels, some one suggested godrej channels. Or should i stick with ebco and hettich?

Hello madam .. Would like to know the merits &demerits of using GLOSSY LAMINATIONS ( Merino MR +) to whole of 3 BHK apartment

Glossy laminates tend to develop tiny scratches over time similar to the scratches on car paint. Also if you use these for the entire house you risk it becoming overwhelming. Usually glossy looks good in the Kitchen and on Sliding door wardrobes.

Rgds

NM

Choice of wood is fine, however note that Green Eco tech is the lowest grade ply in the Greenply range and you may get better quality ply from lesser known brands in the same price range.

Quality of EBCO is comparable to Hettich while the price point is lower, hence ok to use.

Rgds

NM

Gurjan is a type of wood that goes in to making the ply (something like pine wood). It is not a brand. A Gurjan based IS710 grade ISI marked ply is fine to use.

Regards

NM

A 6 mm backing sheet with both side laminate is fine.

For the wardrobe – stick to a single thickness for the carcass, and shutters either 19mm or 16mm. Shelves can be in 12 mm

Rgds

NM

Hi Nanditha,

In my home carpenter work , edge banding finish not came up properly and joints looking un-even.

Is there any way to cover up.

Lamintae thickness is 1mm and edge band thockness i used is 0.8mm.

Thank you.

The thickness of the edge banding should ideally be more equal to or more than that of the laminate. Also the edges have to be flat and smooth before applying the edge banding. You will only get a good finish if the carpenter has a good hand and knows how to apply edge banding, else you may want to go for regular teak beading.

Rgds

NM

Hello mam

Is Century sainik Mr 303 is sufficient for wardrobes?

Carpenter suggesting to use century club marine 710.

Too much of price differences between them

Century MR 303 is good enough for the wardrobes provided that there is no water seepage currently and expected in the future through the walls where the wardrobe is being built

Rgds

NM

Hi nandita,I want to do my kids room(wadrobe,bed and study table) in duco paint.Plz tell me what should be thickness of plywood and mdf sheet.What should be the total thickness of ply+mdf? Plz reply asap if possible as my work is sceduled in 2-3 days.

The table top thickness should ideally be 40mm. The rest should be fine in 19mm. If you are using Duco then try and minimize the joints or sticking 2 sheets together to increase the thickness since the layer of paint on top of the joints usually develops cracks over time.

Rgds

NM

Hi Mam

Iam living in Varthur Area Bangalore, carpenter suggested for Alpine or Pristine Plywood are they good and durable.He said its economical and long lasting .But I have my doubts kindly suggest.

My polish person has given me two option one normal polish and second normal polish with matt coating.

What is matt coating ? Is it worth spending extra 20% ?Is it required for wardrobe, bed and tv cabinet polish ?

I am also using PVC board just for kitchen carcass. I know it's risk and you had posted comments in Dec 2015 when you mentioned it's not a proven material.

But I went ahead with risk as I found it to be durable and appropriate for kitchen. In terms of expense it's almost same or slightly cheaper because I do not require a laminate plus labour is less.

Although only time will tell but I think it has potential to be a good alternative to wood especially for kitchen due to durability, termite and water proof and also fire resistant as compared to wood.

Will be keen to know your views and happy to share my experience.

You may use any genmuine ISI Marked IS 303 MR Grade wood for the dry areas and IS 303 BWR grade wood for the Kitchens/ bathrooms

Rgds

NM

Thanks for the feedback. And good to know that you are satisfied. Do keep a watch on the hinges and the drawer channels as the screw holding capacity of PVC is known to be limited, however with proper maintenance it should be ok.

Rgds

NM

Matt coating is a coating done by a spray gun that gives a matte finish to the polish. It will give a much better finish hence recommended

Regards

NM

Hi,

My designer suuggested to make wardrobes with plywood and their doors with pine wood. Also he suggested to build safety door with pine wood. Pine for avoiding the bending of doors. The wardrobe i am going to build is of 9ft tall. Please advise.

In Bangalore's climate 9 feet high wooden doors in any brand of ply/ board are likely to bend. It would therefore be best to use aluminium/ steel/ wooden framed doors.

Rgds

NM

Hi mam…

I went through your posts…

However I want to know that is particle board fine for wardrobe and in kitchen?

Hi Nandita,

Great blogs and thanks for doing it. I am going for 7ft regular wardrobe with 4 doors. Hence each door will be of 21", do you see any issue with 21" commercial ply doors? What is the max door width for non-sliding wardrobes?

Thank you.

Hi nandita,

I have quieries

1.I am planning to use dyed veneer in kids room.I heard that dyed veneer get fade away over a time.Is it true?

2.What should be thickness edge Banding for veneer?

3.What are good brands of veneer other than euro,century and green?Hw about using Recon veneer?

Will not recommend particle board unless you have a severe budget constraint

Rgds

NM

21 inch hinged door should be fine. You can go upto 2 feet at max with regular hinges and ply/board.

Rgds

NM

Veneer needs a coat of polish on top and it is unlikely that it will fade if the polish is done properly.

You don't need edge banding for veneer as the edges will be polished along with the veneer

I will suggest going with regular brands such as Century, Green, Euro

Rgds

NM

Hi Nanditha,

We are planning to start interiors for our new building.We got quote from Carpenter.He is suggesting to use Same at plywood with Ebco hinges.Is this brand is fine?please let me mat finish for bedroom wardrobes and for TV panels is fine as glossy finish will be used for kitchen.Need your inputs.

Any ISI Marked ply MR grade for dry spaces and BWR grade for moist spaces is fine to use. The typical price will range from Rs 60 – 80psft for MR Grade and Rs 90 – 140 psft for BWR Grade. If it is cheaper than this then the quality is circumspect.

Rgds

NM

Hi

I am planning to do interior for my 2bhk at chennai.

please let me know the list of materials and their grade for

a. kitchen

b. cupboard (shelves are there already just for covering)

c. loft covering

d. tv and pooja units

e. modular kitchen with basic 5 tray only

i am searching for a carpenter who will give the list of materials with quantity and i can purchase from a hardware shop and get the work done from the same person it self.(will this plan work ?)

Material details are available at http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

Rgds

NM

Hi Nanditha,

Really impressed by the way you have clarified all the intricacies of modular kitchen

We are going for a modular kitchen and have few queries in mind. It would be of great help if you can clear the queries:

1) Had read somewhere that the modular kitchen thickness should not exceed more than 16mm. We are going for BWR ply of 18 mm thickness for kitchen cabinets and 19 mm BWP Board for kitchen cabinets door. Please let me know if it is best combination.

2) We are planning for mix finishing in kitchen cabinets i.e going for acrylic finish for upper cabinets and laminates on lower cabinets. Please let me know if it works well and is it ok to have acrylic on ply/board.

Thanks in advance

1. Regular zero crank hinges are designed for 18mm thick shutters and cabinetry – hence it is best to use 16mm ply/board with a finished thickness of 18 mm (both side laminate or inside laminate and outside membrane/ acrylic etc.)

2. For Kitchen shutters (short height) – provided they are factory made/ edge banded – any base material should be ok.

Rgds

NM

Hi,

My designer told me that he will be using alphine plywood for which he said 15 years warranty from company, but today he has bought premium plywood and on the board 25 years warranty has been printed.

please suggest is it ok if we use premier plywood

Regards

CV

If it is ISI marked IS 303 Grade BWR (for wet spaces) and MR (for Dry Spaces) then its fine.

Rgds

NM

Hi Nandithaji,

May please suggest which of the following options is better in terms of the asthetics of bed room doors

1. Laminating the flush door and its frame

2. Painting the flush door and frame with duco

3. Polishing the door and frame

Any other suggestion for adding good looks to the door

Laminating the frame is not recommended as the edges chip off over time. Hence you can either paint or polish the frames. The doors can be laminated or veneered (with polish) – veneer usually gives a richer finish.

If the flush doors are textured then even paint looks good.

Rgds

NM

Please compare home interiors with PVC or wooden material. Please provide advantages and disadvantages of PVC or wooden material.

This topic has been discussed extensively in the comments above – do please browse through. Also go through the comments under the post below

http://www.homedesignbangalore.com/2010/09/so-what-is-right-material-to-choose-for

Rgds

NM

Hi Nandita,

We met lot of people and also went through the posts above.

We would like to know how are Egger brand particle boards.We are told these are treated German boards and are good to use for carcass. Is it so?

Particle board, imported or otherwise, is not recommended unless you have a budget constraint.

Specifically on Egger brand – I have not used this and hence would restrain myself from commenting

Rgds

NM

Hi Nandita,

Whether postform is possible on MR grade and BWR plywood. I am hearing it is possible on MDF/Particle Board only.

Arun

Postform for the edges is possible in Ply, the ply will need to be rounded while for MDF and Particle board it can just be pressed.

Rgds

NM

Hi Nandita,

Firstly thanks a lot for sharing your views with your experience and clearing queries of many of us. I would like to add a bucket of mine to gain some benefit from your expertise. My interior person has shared following details. Please guide which area i can correct it to get better quality.

1) Kitchen :

a)BWP/BWR tuffwood brand Plywood with 0.45mm edge band & 0.8mm off-white laminate for boxing .Fully factory made work. 19 mm ecotech plywood